Compressed air quality testing equipment

Release date: 2023-10-20 11:53:47 Visits: 597

OIL -Check 400

Continuously and accurately measure the residual oil content in the form of steam from 0.001 mg/m2 to 2.5 mg/m2. Class 1 compressed air quality can be monitored through a low detection limit of 0.001mg/m2s (ISO 8573).

PC 400

The high-precision optical particle counter PC 400 can measure particles as low as 0.1μm in size, so it is suitable for monitoring the quality of compressed air at level 1 (ISO 8573).

FA 510

FA510 can measure the pessre dew! pointupto - 80* Cid. Athis time, cont nuous measurement can alsou ensure that the alarm wil be tngere medately when the cmpesedes ar dyoer als.

The ACF laboratory is designed based on the ISO- -8573 compressed air standard, which can inspect and analyze the relevant standards of compressed air filters, such as flration accuracy (dust removal and oil removal) and filter pressure dfference. It can inspect and analyze the classification effect of gas-water separators, and test dew points. This is an important means for enterprises to have research and development capabilities and ensure product quality.

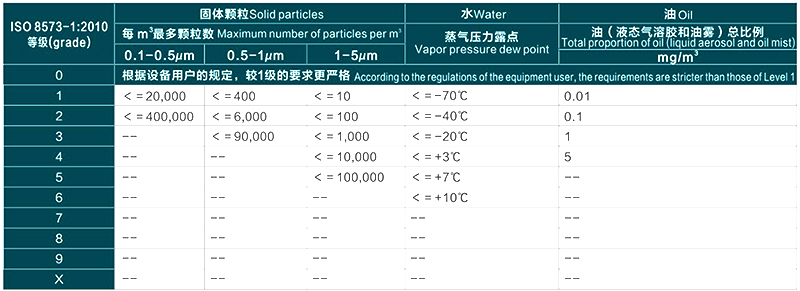

Executive standards

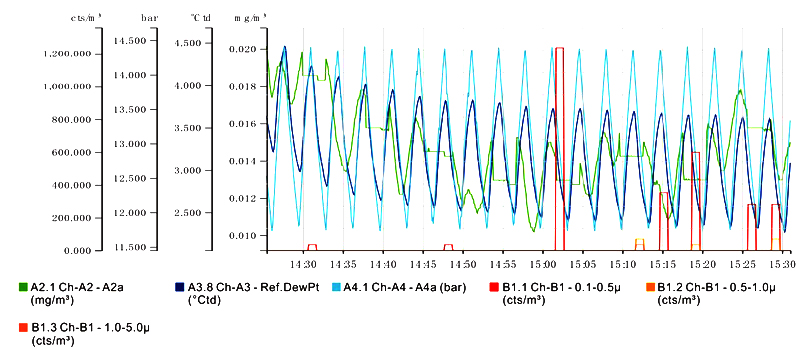

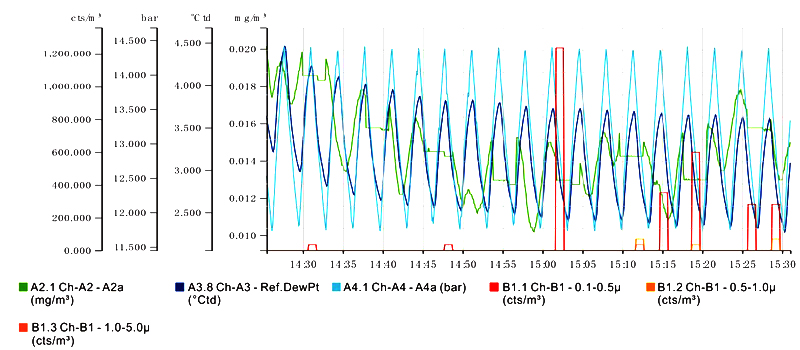

Detection data trend chart

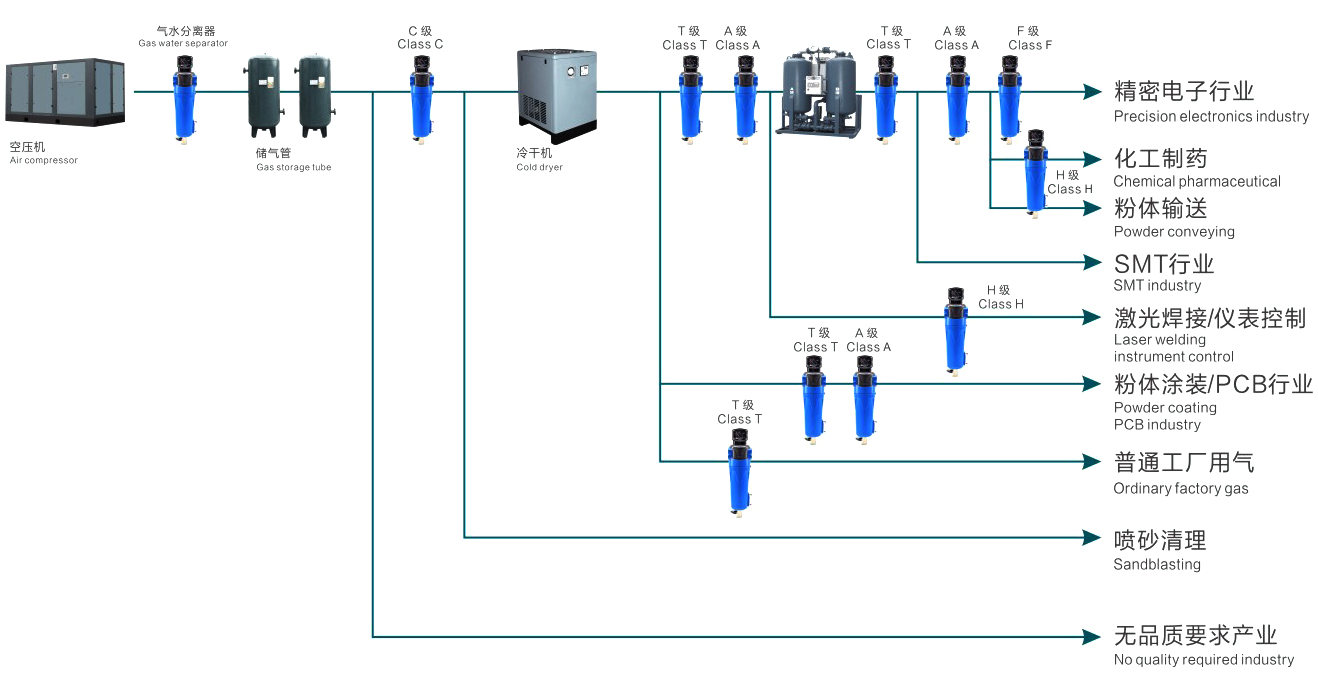

PRODUCT INDUSTRY APPLICATION CONFIGURATION

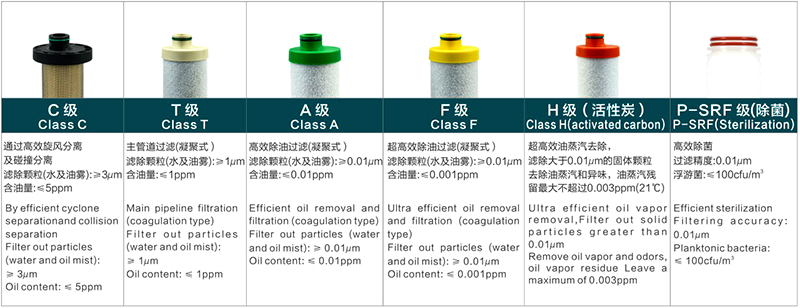

Filter element filtration accuracy and effectiveness

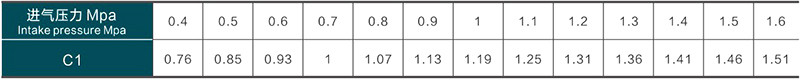

Working pressure correction factor

When the pressure is not 7kgf/cm*, the flow rate of the selected filter should first know the maximum flow at the fiter inlet and then divide by the correction factor corresponding to the minimum pressure of the filter inlet to select the appropriate filter size.

Previous: stainless steel flange filter

Next: ACF Filter